contactor failure analysis

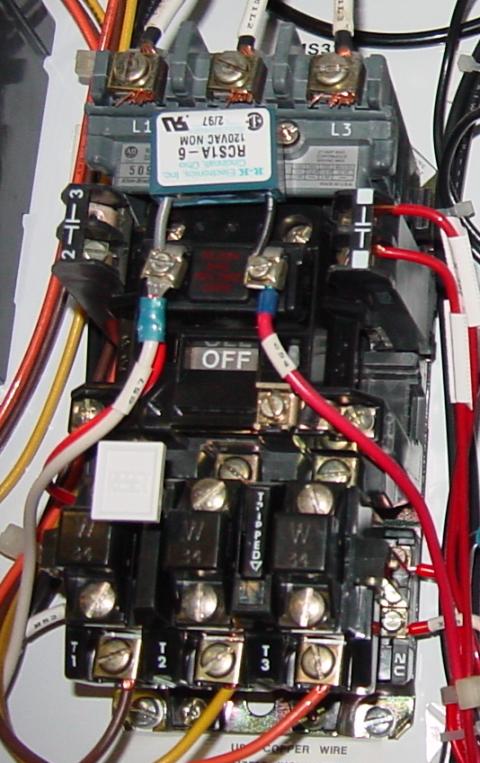

The coil in the contactor is energized to make the armature magnetic and the suction armature drives the moving contact and the static contact to close. See picture below for typical failure.

Contactor Failure Symptoms Reasons For Contactor Failure

Analysis Of Common Failures Of AC Contactors 1 Check whether the coil insulation is damaged due to humid air or corrosive gas.

. Direct on line across-the-line motor starting. Download Citation Failure Analysis of Alternating Current Contactor Alternating current contactor is one of the important elements widely used. In addition to IC chip evaluation and validation the focus is now on failure analysis applications and low inductance laboratory measurements.

V380 V - 50 Hz. Analysis of common faults of AC contactors. 6 Another study more than 281000 circuit breakers in use in 26 countries has shown that 50 of major failures are related to mechanical problem.

This paper mainly concerns failure analysis of the failure contactors after the reliability trial of AC contactor. Coil failure and repair. Common faults of contactors 1.

The typical contact resistant value under common test condition is 5 mΩ which is offered by the manufacturer. The main contact part is ablated the contact surface is uneven or there is oxidized metal attached. Firstly the test device and the test parameters are introduced in brief.

This type of fault usually occurs after the line is short-circuited. Insertion fault The coil is burned out by excitation rush current 1015 times of holding current flowing into the coil if you operate it continuously without perfect inhalation after the power voltage decreases abnormal material penetrates the magnetic contact pole. As the operational limit of any contactor is between 85 Percent and 110 percent of the rated coil.

The results include Maximum Allowable Working Pressures MAWP calculated for the original design with a 116th corrosion allowance and with zero corrosion allowance for actual measured conditions. The HVAC Contactor is what turns on the Compressor and Outdoor Fan for Air Conditioners and. This video is part of the heating and cooling series of training videos ma.

Based on the structure and operation principle of the common clap contactor of electric. The following is an analysis of the coil failure. Welding happens but is often associated with fault currents and so is independent of contactor age or wear.

Disconnection failure contact burnout or welding capacity etc. 3 Check whether the contactor is mechanically damaged. Regardless of the environmental conditions of the electric forklift the common faults of its contactors are mostly the main contacts static and dynamic contacts are not connected or poorly contacted.

Current peaks used by heavy duty starting - If the application requires a high level. In This HVACR Training Video I Show the Top 5 Problems that can occur while Troubleshooting a Contactor. A method to monitor running current through the contactor accurately is thefirst requirement for electronic overload protection.

Both types of fluctuations like over voltages and under voltages cause contactor failure. Waross Electrical 15 Jul 18 1621. 10203 views Apr 22 2014 This one shows a contactor that may have caused a compressor failure diagnosis.

Monitoring the condition of the contacts may be quite expensive and may not be that reliable. So its reliability level is very important. 2 Check whether there is any wire break inside the coil.

Typical Connector Failure Modes and Mechanisms - Connector and Cable Assembly Supplier. Examples of common reasons for contactors not working properly is causing the voltage to drop. Variation in voltage is another cause of the failure of the contactor.

According to an international study more than 70000 circuit breakers in use in 22 countries has shown that 544 of severe failures and 493 of minor failures are due to mechanical causes. According to the data obtained from the test this type of electromagnetic relay had degraded after long-term storage. Alternating current contactor is one of the important elements widely used in the automatic control system.

The Connector Basics series from APEX Electrical Interconnection Consultants continues with an introductory look at typical connector failure modes and mechanisms. A second common failure of AC coils is caused by mechanical vibration wherein one or more turns short internally as. The main contact resistance is too large.

One common failure of AC coils is failure of the contactor to fully close to complete the magnetic path. Design Pressure 643 psi Design Temperature 650 F Shell Head Materials A212 Gr. With the path openthe coil continues to draw too much current resulting in overheating and failure.

Nozzles flanges and fittings were all evaluated. The simplest method is to use a precision resistor as a shunt and simply measure the voltage across it. If the wire is broken replace the coil with a new one.

Actually most of the devices contact resistance value was greater than 35 mΩ and 10 samples failed. IC Test Contactor for Failure Analysis 21 May 2021 - The Y-RED test contactor series from Yamaichi Electronics is growing. The overwhelming number of failure of motor contactors are failure to close.

In the process of theoretical research and test verification it is shown that when the switch equipment is opened the voltage and current between contacts do not change in a moment but arc burning occurs at the separation time of con-tacts which will cause contact failure when the contact erosion reaches a certain threshold. Too high continuous control voltage could also cause the coil to melt. Therefore whether the coil is strong or not plays an important role in the reliable connection of the contactor.

The method is very accurate but can generate considerable heat in highcurrent contactors. The common contactor coil failures are.

Contactor Failure Symptoms Reasons For Contactor Failure

Common Reasons For Contactor Failure

Top 5 Hvac Contactor Troubleshooting Problems

Contactor Failure Symptoms Reasons For Contactor Failure

How To Make Automatic Changeover Switch Change Over Switch Using Contactor Electrical Technician Youtube Transfer Switch Electricity Switch

Real Cases Of Magnetic Contactor Failure Impact On Power Plant Process Possible Causes Of Failure Corrective Actions Taken Comprehensive Overview

Contactor Failure Symptoms Reasons For Contactor Failure

What Can Be Caused By Contactor Failure China Nanfeng Electric

Common Reasons For Contactor Failure

What Can Be Caused By Contactor Failure China Nanfeng Electric

Marine Safety Alert Verify Launching Appliance Winch Component Rating Maritime Commons

Reasons Of Contactor Failure Contactor Troubleshooting Youtube

Motor Circuits And Control Applied Industrial Electricity

What Can Be Caused By Contactor Failure China Nanfeng Electric

How To Test A Contactor Youtube

Reasons Of Contactor Failure Contactor Troubleshooting Youtube

What Causes A Contactor To Fail Youtube

Top 5 Hvac Contactor Troubleshooting Problems

Top 5 Hvac Contactor Troubleshooting Problems

0 Response to "contactor failure analysis"

Post a Comment